|

|

#91

|

||||

|

||||

|

The chemical dipping process can be expensive since they apparently charge by weight and not by surface area. So anything armor will cost quite a bit more than sheet metal panels or small parts and brackets. That could well be part of the reason why they did my hull for such a cheap price as they saw pictures and we talked it up and made a deal before they ever got back to asking how much it all weighed. If the price had been what they want to charge others for the work now, I wouldn't have used the service due to my budget at the time.

But knowing what I do now that it's done and I've seen the results, I think I would still dip it if I were to start another project. The chemicals can clean out areas that sand blasting wouldn't be able to reach. In terms of what Lynn said about the floor on a sand blasted carrier rusting after the fact, I was worried about that on mine before I found the chemical dip place. Part of my rusty floor looked flat and smooth while other areas were deeply pitted. I tested it with a hammer and was able to break off some of the flat areas and found the wavy pitted metal underneath. So I ended up getting my air chisel and went over the entire floor several times. That left my entire floor wavy and pitted but it was at least solid metal. I figured a sand blaster would only be able to work the exposed metal so didn't want to have a problem later on. Odds are the chemical dipping would have gotten to most of the lower layer on its own but I still would have had problems I think since I'd have primed the upper surface metal that might have broken off later. So I'd recommend anyone planning either process should go over the floor really well before hand. You might tear off a lot of metal but it's not good metal. That way any needed repairs can be done before you have everything striped and primed. I'm not sure why the original floor was as I found it. It really seemed like a thin sheet of metal had been laid over the thicker armor hull down there at first. And water got between them and rotted one underneath and weakened the upper layer from beneath it. Must be part of the old laminated armor process where the outer edges are hardened and the inside is left mild.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#92

|

||||

|

||||

|

Very interesting posts Lynn and David. It has got me thinking. Years ago when I first recovered 2 pounder Carrier 6146 from rural NSW I filled up the hull with warm water and molasses and left it to work for a week or two. I seem to remember that the result was pretty good but not perfect.

I am thinking of trying citric acid in the scout carrier for two reasons: 1/ we use it almost daily at the Military museum and so far has provided some fantastic stripping results and at a very moderate cost (as well as environmentally and persaonnaly safe) 2/ Surprisingly enough the interior of the Scout hull is actually very good - in parts where the original finish of the armour can be seen it appears almost like new - it's just that almost everything else has a thick layer of rust and many of the original bolts have become compromised. The outer and especially the upper armour is in good condition save for a thick rust encrustation and I might consider the old trusty wire wheel (or a few of them) if the citric acid works well enough. It might sound very slow and labour intensive but when you are 300km's from the nearest industrialised city you have to make-do Wish me luck Cheers Phill

__________________

Ford GPW Jeep USMC Ambulance Willys MB Jeep Daimler Ferret Mk 1 Daimler Ferret Mk 2 Land Rover S2A Field Workshop Land Rover S3 FItted For Radio x2 Land Rover Perentie GS (SASR) International No 1 Mk 3 2.5 Ton 4x4 International No 1 Mk 4 2.5 Ton 4x4 Last edited by Philliphastings; 20-05-10 at 06:14. Reason: typos |

|

#93

|

|||

|

|||

|

There are many products on the market that are based on phosphoric acid.

you paint the stuff on and it kills the rust. I'd do that, and then blast it. Forgive me for preaching here, but what you have in the scout is unique, and needs a good job done of her. No half measures. If you do it well, you will be proud of her, and she will be worth a pretty penny.

__________________

Bluebell Carrier Armoured O.P. No1 Mk3 W. T84991 Carrier Bren No2.Mk.I. NewZealand Railways. NZR.6. Dodge WC55. 37mm Gun Motor Carriage M6 Jeep Mb #135668 So many questions.... |

|

#94

|

||||

|

||||

|

Yep, I live by the wire wheel mounted on a 4” angle grinder as well. Even tried sections of the hull that way but found there were too many places it couldn’t get into and they were usually the most in need. Plus like I’d mentioned before, my floor was deeply pitted after air chiseling the top crust off and the wire wheel wasn’t very effective getting into the moguls without excessive pressure being applied which reduces the life of the wire wheel or wire cup, plus the motor on the grinder.

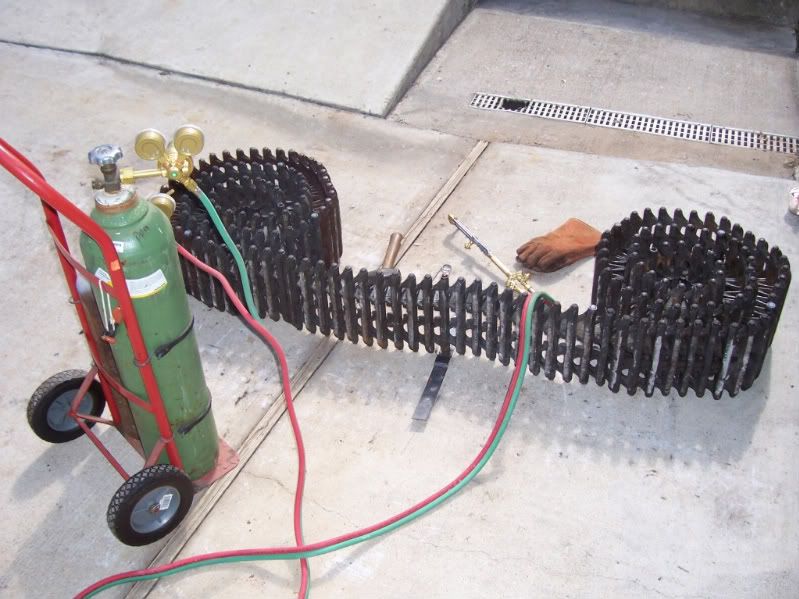

I experimented with phosphoric acid when trying to figure out a good way to get my tracks freed up. They had been rolled and stored for a long time before I got them and required a breaker bar to force unroll them due to heavy rust. I broke them into sections and made my own chemical bath to test two sections. Results were visible after a few days but it was going to take a lot of work to free up each link since they would need to be moved back and forth a bit and then soaked again. This would need to be repeated over and over until the section was good again. After getting the two test sections done, I looked back at the stack of waiting sections and decided to seek out a more cost effective solution. The molasses trick is an old one that most people have had good results with. But I couldn’t find an affordable source for bulk molasses here in Texas, even checking with the cattle feed and supply stores. Basically it was by the gallon like the phosphoric acid and wasn’t cheap. Space and a way to deal with the mess was also a concern for me working in a residential neighborhood. The ideal thing would have been a large galvanized metal horse trough for placing both tracks in with the chemicals. Then they could be worked on and off while flipping them around inside.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#95

|

|||

|

|||

|

Quote:

Light a big fire and drop the track in to heat them up for an hour or so..Pour the coal to it and get them nice and hot.....Then Hook a chain to them and drag them around the back 40 for a while..That will loosen them up.. Comes with a money back guarantee...

__________________

Alex Blair :remember :support :drunk: |

|

#96

|

|||

|

|||

|

I soaked mine in free 2nd hand hydraulic oil, for weeks. Then I used two pry bars, between adjacent links, to get them moving. Most freed up. The worst , I used the gas on, and sacrificed every 2nd link. It uses a lot of gas.

__________________

Bluebell Carrier Armoured O.P. No1 Mk3 W. T84991 Carrier Bren No2.Mk.I. NewZealand Railways. NZR.6. Dodge WC55. 37mm Gun Motor Carriage M6 Jeep Mb #135668 So many questions.... |

|

#97

|

||||

|

||||

|

diesel oil(or furnace oil) mixed with used tranny fluid might work as well

|

|

#98

|

|||

|

|||

|

I haven't tried it but this interesting thread reckons Automatic Transmission Fluid mixed 1:1 with acetone makes a top-class penetrating oil, comparable to the expensive offerings:

http://www.lotuselan.net/forums/viewtopic.php?t=14602 Steve. |

|

#99

|

||||

|

||||

|

I haven't tried phosphoric acid yet for the simple reason that citric acid has shown no adverse aspects at all so far. The stuff is so harmless you could almost drink it and it certainly does no harm to plunge bare arms up to the elbows in when fishing out treated parts. It is apparently a by-product of the wine making industry...

Yes transmission oil works well where you need a lot of penetrating fluid. Very good for seized engines if poured into the cylinders and left to work it's magic and claggy gearboxes which have to be stripped down anyway. Cheers Phill

__________________

Ford GPW Jeep USMC Ambulance Willys MB Jeep Daimler Ferret Mk 1 Daimler Ferret Mk 2 Land Rover S2A Field Workshop Land Rover S3 FItted For Radio x2 Land Rover Perentie GS (SASR) International No 1 Mk 3 2.5 Ton 4x4 International No 1 Mk 4 2.5 Ton 4x4 |

|

#100

|

|||

|

|||

|

Phosphoric acid is no good for cast iron or high tensile. The reason I never went down the acid track was that I thought it might help to lock things up. where as oil has the opposite effect, and the warnings about lubing the track, refer to a different situation. Once, and left to drain(while your rebuilding the carrier) are not going to cause any long term harm.

__________________

Bluebell Carrier Armoured O.P. No1 Mk3 W. T84991 Carrier Bren No2.Mk.I. NewZealand Railways. NZR.6. Dodge WC55. 37mm Gun Motor Carriage M6 Jeep Mb #135668 So many questions.... |

|

#101

|

||||

|

||||

|

Years ago good old Coca Cola was super for removeing rust and loosening rusty items. But think the Coke sold now is not the same as the old stuff I drank as a kid

|

|

#102

|

||||

|

||||

|

Diesel fuel is what I’ve used in the past for soaking parts needing to be broken free and for locked up engines, but it won’t really remove rust. For the tracks, I know that simply running them would have cleaned them up over time once the pins and links were freely moving but I worried about being able to get them loose enough to install and then freely moving without risk of breaking track pins which are getting hard to source and a bit expensive.

My tracks were pretty stuck having been stored in rolls for an unknown amount of time outside. After forcing them flat with the breaker bar and getting pins cut so I’d have tracks in smaller sections, some were still so stiff that you could hold it up at each end and it wouldn’t sag whatsoever in the center. Most could be stood up on end like boards so you know that there would have been no easy way to attempt installing them to run them until free.    The people that dipped the hull were willing to do the tracks when they did the other work since it was still part of the project they were doing as a test. They ended up soaking them over a three day extended weekend initially. Then took them out and washed them down so that the links could be worked back and forth by hand. Then soaked them again the next weekend so the chemicals could really get inside where the pins might have been sticking after that first bath. What I got back were tracks that a little kid could easily roll up by hand. I didn’t expect to be ready to install the tracks for a year or more so decided to leave them in sections for easier handling. I used a spray grease to coat the outer surface since the shed they would be inside wasn’t sealed from the elements and I didn’t want the tracks locking up again if they ended up being stored a lot longer than I planned.   When I was ready to put the tracks together, I took the sections to a local car wash (at night after hours) that had a high pressure wand with soapy hot water. Blasted everything clean of grease since I knew the tracks needed to be used without lubricant as it would attract dirt and sand which is abrasive to the pins and link sockets. Used my torch to heat up pin ends and made my own rivet domes as I put the sections back together so they would look like an original factory track. After that the installation was simple, even for a novice like myself.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#103

|

||||

|

||||

|

At the risk of sounding like a broken record - Thankyou very much once again David for a first class post!

Very informative and excellent images. Cheers Phill

__________________

Ford GPW Jeep USMC Ambulance Willys MB Jeep Daimler Ferret Mk 1 Daimler Ferret Mk 2 Land Rover S2A Field Workshop Land Rover S3 FItted For Radio x2 Land Rover Perentie GS (SASR) International No 1 Mk 3 2.5 Ton 4x4 International No 1 Mk 4 2.5 Ton 4x4 |

|

#104

|

||||

|

||||

|

Credit goes to the little critters that can get into small places and hold a box wrench on a nut that nobody else can reach. Sure saves a lot of time by not having to rig something up to hold an item in place when typically working alone.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#105

|

|||

|

|||

|

Quote:

Cell 678-665-3623 Home 770-719-2365 |

|

#106

|

||||

|

||||

|

Three shots of an aerial carrying case number 1 which I recently got from Lance via MLU sales. It fits the mountings on my T-16 and extends right up to the edge of my 4.2-inch mortar ammunition bins like it was made for it.

Now I just need to clean it up a bit. It's really nice when things come together like they were planned from the start. A rare thing for me anyway.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#107

|

|||

|

|||

|

very envious david, mind you there would not be much point in me having bought it as I mine is now in so many pieces it coudl be years before I have something to hang it on!

Just one thing, do you know what the stirrup bracket is bang in the middle of the vehicle in extending down into the driver/gunner compartment? It has always confused me as it looks like it is canted towards the gun port? |

|

#108

|

||||

|

||||

|

Hey Andrew,

That would be for the PIAT when in the "ready" position. The rear mount just in front of the radiator and the front mount is in the front armour near the gunner ports. It swivels out of the way when not needed. They didn't fire from this position but it held the weapon in a convenient place for quick access. Similar to the forward Bren mounts under the sloping front armour. Has your restoration bogged down? Thought you were making great progress on it.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#109

|

|||

|

|||

|

Thanks for the informaion on the Piat David. No not really bogged down but the weather has been appalling over here and since most of the work I do is outside in an open barn I have slightly slipped. I also, was trying to time the hull to be welded and then blasted and painted when the weather is a little better. There is so much moisture in the atmosphere at the moment it will be better in the Spring. I am also struggling with the engine shop who are taking out the valves for me and steaming the whole block, honing the bores and putting the valves back. The reason i am not doing them is my Valve grinding machine is 200 miles away at my fathers workshop and that will make doing the tappets rather time consuming. To be honest, with the holidays and weather I have let it slow a bit, but am right back on it today, see my other post!!

|

|

#110

|

||||

|

||||

|

Glad it all worked out for you Dave.... I have some other news for you, will send you a email offline of a upcoming purchase!!!!!!

__________________

39 Austin 8 Tourer 42 Humber Heavy Utility 42 C15A Wireless Truck 43 Humber AC MK IV F133744 "Vandal" tri-owner 43 A27L Centaur MK III T185481 |

|

#111

|

||||

|

||||

|

Been busy with the day job and tinkering on the jeep during spare time for a WWII vehicle rally we attended last week here in Texas. I could hear the carrier crying for attention and noticed the tracks were looking pretty slack on both sides so decided to address that problem so it would be good to go next time I was able to get it out for a run.

I've had 172 links on the driver side and 173 on the gunner side for the past year and a half. Wanted to have a matching link count on both sides though to make it easier to remember and to see if the vehicle would drive straighter on long flat paths. Old discussions on a Weasel forum always indicated an uneven count would cause a vehicle to need constant adjustment with one tiller bar and that would eventually lead to more wear on brake related parts on the opposite side compared due to steering corrections. Not sure if this is really true but figured it would still be best if I could even them up since both sides needed to be tensioned anyway. I was able to take up the slack on the driver side using the cam adjusting tool. The gunner side had the extra link removed and only needed minor adjustment with the cam after that. So now I'm running on 172 links on each side. Think 168 is the dead or dying track indicator for a T-16 so I guess I have plenty of life remaining on this set given the limited miles it gets driven per outing.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#112

|

|||

|

|||

|

Hey well done David, good to see that you are always keeping your beautiful restoration on top form. I am sure that an uneven count would make it drive to one side or another. I cant quite think how that works but it seems to make sense to me, maybe just different reactions to undulations in the road at its simplest would cause a movement to left or right?

What you need is a proper track jack to make the job quicker! |

|

#113

|

||||

|

||||

|

The tool I've always used for the tracks so far is a modern US type that I modified. Had to grind the hooks down quite a bit so they would work with the T-16 carrier track links. It does the job but can be a pain holding it in contact with the track with one hand, while cranking the central nut around with the other until there is enough tension to keep it in place. One shot shows a crescent wrench holding the track up. That was so I could tighten up the track enough to make up for the link I took out. Before getting the track broke, all wrench work had to be done in the limited space underneath the track.

I'm still unsure about the different length tracks causing the vehicle to creep to one side as it drives. Seems like the speed of the turning drive sprocket would be the only factor. If you put the vehicle down on a mile length of flat carrier tracks, it would simply crawl along it if everything was locked to spin each side at the same speed. Sure someone with more mechanical engineering smarts knows the answer for sure. Still happy to have the same number of links on each side now either way.  And one day I'll hopefully have a proper track jack

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#114

|

||||

|

||||

|

Another evil reproduction part about to be primed, painted and bolted into my carrier.

But until I can find a good useable original set, I'm very happy with these. But until I can find a good useable original set, I'm very happy with these.  I had an example of the short section which was recovered from a carrier that was rotting somewhere up in the northern Canadian tundra. It's been sitting around for almost three years and Ray was able to get one of his business associates to fabricate duplicates along with the longer section. These go on top of the floor locker located behind the driver in the T-16. The short section holds the floor board in place and the long section is the battery tray.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#115

|

||||

|

||||

|

Warm weather and longer days means it's time to get back to work on projects...

Got the floor lockers installed again behind the driver and gunner in the engine bay. The driver side locker gets the pair of metal racks with one intended for the short floor board and the other under the radio area for the vehicle battery. The gunner side has no racks and gets a full length floor board since they didn't always have the seat up by the radiator. There are no details about the two floor boards anywhere that anyone has found so far, but you can spot each of them in a couple of the wartime photos/drawings they included in the parts and service manuals.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

#116

|

|||

|

|||

|

Heres my explanation of why the carrier heads in one direction,when the track link numbers are uneven. It comes from the tendancy for the drive to come out of a differential evenly, particulary under load. Just like in a slippery diff, the planetary and side gears tend to push away from each other. The result is they tend to lock against the thrusts, and in turn the differential case. This has the effect of the whole unit turning as one including the sprockets with their thirty five teeth. It takes just that little bit longer for a track with extra links to get back around, and so the machine starts to head to one side. Of course this tendancy is easily overcome by the application of a bit of steering or brakes, or the effect of uneven terrain

__________________

Bluebell Carrier Armoured O.P. No1 Mk3 W. T84991 Carrier Bren No2.Mk.I. NewZealand Railways. NZR.6. Dodge WC55. 37mm Gun Motor Carriage M6 Jeep Mb #135668 So many questions.... |

|

#117

|

|||

|

|||

|

Lynn, the sprocket doesn't know how many links are in each track. If you short track a vehicle on one side it drives the same, all other things being equal.

That is where the tendency to pull lies in my opinion. Minor differences in track tension and road conditions.

__________________

Adrian Barrell |

|

#118

|

|||

|

|||

|

With all due respect to your knowledge and experience with tracked vehicles. The point is that, every thing else being the same, tension etc,and the only difference is that one track is more worn than the other, and therefore has one less link than the other side. the machine heads off to one side.

The workshop manual descibes the fault, and how to fix it. By making sure the two tracks have the same number of links each side, and by quarting the two tracks, and swaping the quarters to give equal length tracks.

__________________

Bluebell Carrier Armoured O.P. No1 Mk3 W. T84991 Carrier Bren No2.Mk.I. NewZealand Railways. NZR.6. Dodge WC55. 37mm Gun Motor Carriage M6 Jeep Mb #135668 So many questions.... |

|

#119

|

||||

|

||||

|

If your track is stretched more on one side and your sprockets are worn this means that when the track goes around the sprocket teeth they will not mesh correctly, and will ride up on the side of the teeth. If they do that all the way round the sprocket then more track is going round the sprocket than was designed to do. This surely would mean it takes longer, or is it shorter, for the track to go round that sprocket. If the other side is ok and meshes correctly then would the carrier not have a tendency to veer to the side? Or have I just had two too many of the barley water?!!!!!

Nigel

__________________

He that blaws in the stour fills his ain e'en 1942 Ford Utility 11YF 1942 10cwt GS Trailer |

|

#120

|

||||

|

||||

|

My limited engineering knowledge makes me think the size and speed of the turning sprocket is the big factor here. Not the length of the track itself. Assuming the tracks are both the same in terms of pitch and condition so they stay engaged with the sprocket teeth. So the differential regulating power to each side comes into play. A longer track would have more weight but since the vehicle rolls on it, that should also not be a factor.

In the end, going with what seems right prevailed. Make the track link count the same on each side and then tension each track so it looks the same on each side. If it continues to pull slightly to one side, I'd guess that would be due to rod tension for the brakes and steering which can be adjusted after a few turnbuckle revolutions to take pressure off the differential parts.

__________________

David Gordon - MVPA # 15292 '41 Willys MB British Airborne Jeep '42 Excelsior Welbike Mark I '43 BSA Folding Military Bicycle '44 Orme-Evans Airborne Trailer No. 1 Mk. II '44 Airborne 100-Gallon Water Bowser Trailer '44 Jowett Cars 4.2-Inch Towed Mortar '44 Daimler Scout Car Mark II '45 Studebaker M29C Weasel |

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| my C15 restoration | rampant rivet | The Restoration Forum | 111 | 26-12-19 14:46 |

| M38 CDN Restoration | donjunior | Post-war Military Vehicles | 1 | 08-07-13 03:25 |

| 4.5 Restoration | James Shopland | The Gun Park | 7 | 18-03-13 17:38 |

| F8 for restoration | david moore | The Softskin Forum | 32 | 21-06-05 15:47 |

| Restoration tip........ | Bob Carriere | The Restoration Forum | 3 | 09-08-03 17:50 |